Streamline workflows and eliminate the use of printed materials

Digital Workflows

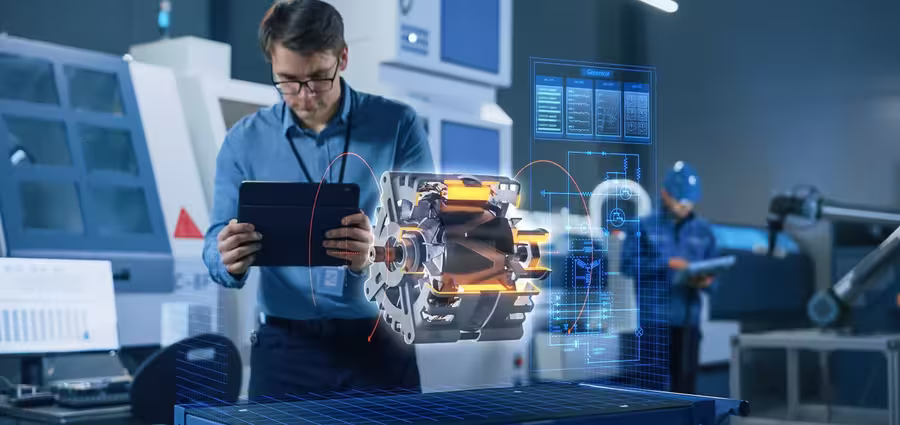

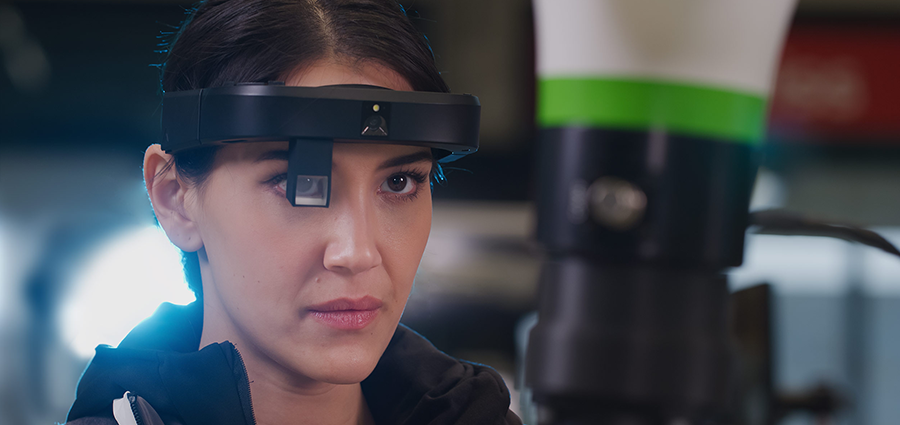

For digital workflows in industry, various mobile devices such as computers, phones, tablets, and smart glasses can be used, each offering its specific advantages. The most effective approach is usually the correct combination of these technologies, depending on the situation and use. Smart glasses provide a key advantage – they display precise information right before the eyes and guide the worker step by step through complex processes or checks. This ensures that all tasks are carried out in the correct order and with the required quality. Additionally, the use of augmented and mixed reality speeds up the training of new workers and increases work efficiency.

Speed up training and standardize procedures

Digital workflows on smart glasses, tablets, phones, or computers make training easier and accelerate the integration of new employees. Digital instructions allow them to learn independently and work more efficiently.

At the same time, they help standardize processes and eliminate errors during maintenance or servicing. Instructions may require confirmation, photo documentation, or automatic AI verification. Mobile devices can be connected to measuring instruments or thermal cameras, expanding their use in industry.

Wide possibilities of digital workflows: 2D, 3D, AR, and VR

Digital workflows can be created in 2D or 3D, using CAD models in augmented (AR) or virtual reality (VR). We offer various software options, including versions where the customer can easily create workflows on their own after training. We also enable full integration with CAD/PLM systems, such as for AR instructions in Siemens Teamcenter or other PLM platforms. The key is that the solution must be intuitive for both end users and workflow administrators.

The main advantages

Benefits of use

faster gearbox inspection

By integrating smart glasses and appropriate software into the assembly process, the time taken to inspect helicopter gearboxes has been reduced by 40%.

less rework

Visualizing orders to the operator via smart glasses and continuously tracking parts in production led to increased paint shop efficiency and a 90% reduction in rework.

shorter acceptance of manufactured buses

Inspection and acceptance of finished buses into service has been significantly simplified and shortened by 30% through the use of smart glasses with assisted reality.

increase in technician productivity

Smart glasses with augmented reality helped to immediately increase the productivity of the technicians, who were able to connect the control unit to the wind turbine 35% faster.