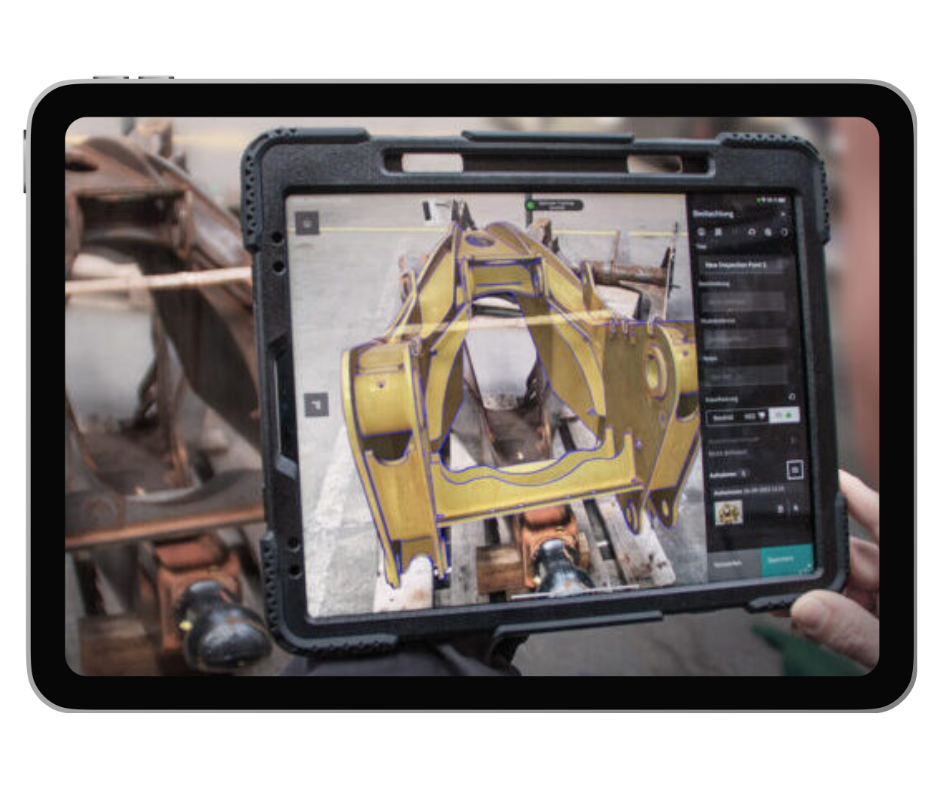

Twyn Visometry software allows quality engineers to perform augmented reality (AR) inspections, significantly reducing inspection costs. This efficient and easy-to-use tool helps improve product quality, meet production requirements and maintain high quality standards.

With Twyn Visometry, you can perform real-time inspections at any location and instantly see if part geometries are correctly positioned, no parts are missing from the assembly, and all parts are correctly assembled. Using Twyn software, you can load the CAD model, set the initialization position, and then link it to the iPad app. It offers sharing options via third-party services or your own cloud.

Twyn’s features are diverse and offer a wide range of benefits. In addition to the ability to quickly and easily analyze abnormalities, Twyn uses your device to automatically register and track inspected items based on a CAD model.

Some of its features include:

- Visual comparison of the underlying data with the final product using augmented reality

- Object registration and abnormalities detection

- Powerful visualization tools

- Efficient and intuitive workflow

- Documentation and reporting features

Photo & Video

Guided quality checks

Features: Inspection Viewpoint Indicators

Simulating & Verifying Assembly of a Speaker

AR Application: First Article Inspection

Areas of application of Twyn software

3D data visualization

for accurate and efficient work in the real world or virtual reality

Quality control & assurance

to improve control checks and gather data